Boost to Atmanirbhar Bharat: Gujarat to host India’s first private satellite plant in Sanand, Azista Space launches Electro-Optical Payload Factory

The history of Indian space exploration has always been linked to Gujarat. The dream envisioned by Dr Vikram Sarabhai from the land of Ahmedabad is now being realised in Khoraj, Sanand. Till now, the work of making satellites was solely the responsibility of the government organisation ISRO, but now, under Prime Minister Narendra Modi‘s ‘Atmanirbhar Bharat’ and ‘Make in India’ campaigns, the space sector has been opened for private participation. At the centre of this revolution is currently Sanand in Ahemedabad district of Gujarat. The foundation stone of the country’s first integrated private satellite manufacturing plant was laid in Sanand on Thursday, 22nd January. Azista Space has laid the foundation stone of India’s ambitious ‘Electro-Optical Payload Factory’. This state-of-the-art factory will be built in Khoraj Industrial Estate, Sanand. Science and Technology Minister Arjun Modhwadia completed the laying of the foundation stone and inauguration of this factory. Many things are associated with this plant, like the Central Government’s ‘Atmanirbhar Bharat’, ‘Make in India‘ and the Gujarat Government’s vision of a developed Gujarat by 2047. Today, we will discuss this entire plant and the benefits it will bring to Gujarat and India in the future. Image of Bhumi Puja (Source: Gujarati Jagran) What is this project? The name of this project is Electro-Optical Payload Factory, also known as the ‘Palmnaro’ plant in the company’s internal context. This is the first integrated satellite manufacturing unit of the private sector in India, where the complete end-to-end production of the satellite will take place – that is, design, engineering, component manufacturing, assembly, integration, testing and qualification – all work will be done at one place. The plant will focus on advanced optical payloads such as high-resolution imaging, remote sensing and multispectral cameras, which are useful for both civil, i.e. agriculture, environment, disaster management and defence sectors. The plant will be set up in Khoraj Industrial Estate, Sanand, Ahmedabad, where the factory will be constructed in the area from plot number K-19 to K-24/1. From research to end-to-end satellite manufacturing, Gujarat is stepping into a new era of high-tech innovation.This landmark facility reflects our commitment to Make in India, build future-ready capabilities, and empower India’s private space ecosystem.#SpaceTechnology… https://t.co/iesCaleakR— Harsh Sanghavi (@sanghaviharsh) January 22, 2026 The foundation stone of this plant was laid by Gujarat Science and Technology Minister Arjun Modhwadia on Thursday, 22nd January. During this, MoUs worth over ₹500 crore have been signed with the Gujarat government for the development, infrastructure and technology transfer of this plant. Under these MoUs, the Gujarat government will provide land, incentives, and support to strengthen India’s private space ecosystem. Azista details Azista Space is an Indo-German joint venture, comprising Azista Industries Private Limited (India, Hyderabad-based) and Berlin Space Technologies GmbH (Germany). The company already has Asia’s first private satellite factory at Plot No. 16, Sarkhej-Sanand Road, Sanand GIDC, Ahmedabad, which is equipped with 30,000 sq ft of clean rooms, AIT (Assembly, Integration & Testing) lab and testing facilities. The existing factory has the capacity to manufacture 50 satellites annually, with a capacity expandable to 250, and 80%+ of the sub-systems, such as power system, communication, and control units, are manufactured in-house. This speeds up the build time by 250 times and reduces the cost by 40 times. Azista’s factory in Sanand (Source: Azista website) The aim of this new plant The new plant is not just intended to manufacture spare parts or payloads, but to prepare for mass production. This will enable fast and cheap supply for mega-constellations (networks of thousands of satellites, such as Starlink). The main objective of this plant is to produce fully indigenous satellites and advanced optical payloads in India by the private sector. It will be an end-to-end integrated facility, where everything from design to final production, testing and qualification will be done under a single roof. The plant will have state-of-the-art facilities, such as advanced clean rooms, calibration labs and R&D centres, thereby reducing dependence on imports and making Indian satellites competitive in the global market. Azista’s main achievement The company’s major achievement is the ABA First Runner (AFR) satellite. This satellite is the maiden (first) satellite of Azista BST Aerospace. It is the first such high-performance remote sensing satellite built by India’s private space sector, weighing 80 kg and designed for wide-swath medium-resolution optical imaging. ABA First Runner (AFR) satellite (Source: Azista website) It is worth noting that the satellite weighs only 80 kg – that i

The history of Indian space exploration has always been linked to Gujarat. The dream envisioned by Dr Vikram Sarabhai from the land of Ahmedabad is now being realised in Khoraj, Sanand. Till now, the work of making satellites was solely the responsibility of the government organisation ISRO, but now, under Prime Minister Narendra Modi‘s ‘Atmanirbhar Bharat’ and ‘Make in India’ campaigns, the space sector has been opened for private participation.

At the centre of this revolution is currently Sanand in Ahemedabad district of Gujarat. The foundation stone of the country’s first integrated private satellite manufacturing plant was laid in Sanand on Thursday, 22nd January. Azista Space has laid the foundation stone of India’s ambitious ‘Electro-Optical Payload Factory’.

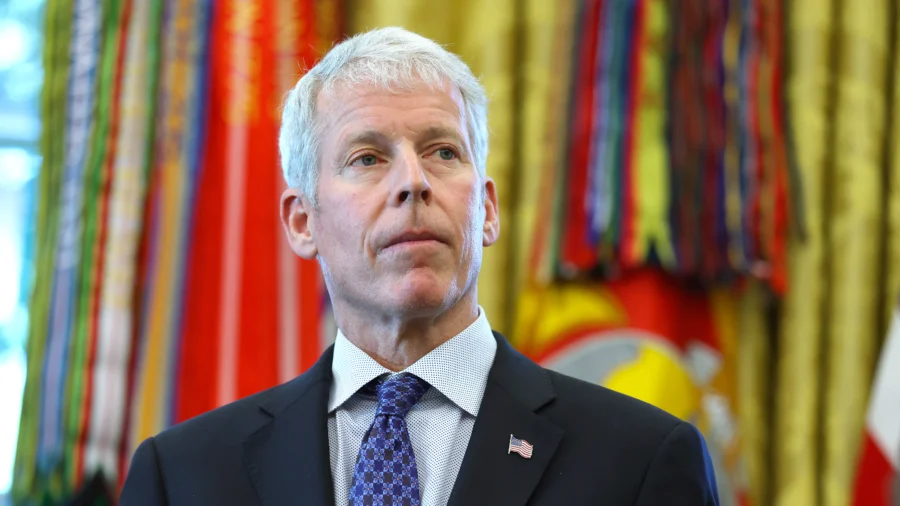

This state-of-the-art factory will be built in Khoraj Industrial Estate, Sanand. Science and Technology Minister Arjun Modhwadia completed the laying of the foundation stone and inauguration of this factory. Many things are associated with this plant, like the Central Government’s ‘Atmanirbhar Bharat’, ‘Make in India‘ and the Gujarat Government’s vision of a developed Gujarat by 2047. Today, we will discuss this entire plant and the benefits it will bring to Gujarat and India in the future.

What is this project?

The name of this project is Electro-Optical Payload Factory, also known as the ‘Palmnaro’ plant in the company’s internal context. This is the first integrated satellite manufacturing unit of the private sector in India, where the complete end-to-end production of the satellite will take place – that is, design, engineering, component manufacturing, assembly, integration, testing and qualification – all work will be done at one place.

The plant will focus on advanced optical payloads such as high-resolution imaging, remote sensing and multispectral cameras, which are useful for both civil, i.e. agriculture, environment, disaster management and defence sectors. The plant will be set up in Khoraj Industrial Estate, Sanand, Ahmedabad, where the factory will be constructed in the area from plot number K-19 to K-24/1.

From research to end-to-end satellite manufacturing, Gujarat is stepping into a new era of high-tech innovation.

— Harsh Sanghavi (@sanghaviharsh) January 22, 2026

This landmark facility reflects our commitment to Make in India, build future-ready capabilities, and empower India’s private space ecosystem.#SpaceTechnology… https://t.co/iesCaleakR

The foundation stone of this plant was laid by Gujarat Science and Technology Minister Arjun Modhwadia on Thursday, 22nd January. During this, MoUs worth over ₹500 crore have been signed with the Gujarat government for the development, infrastructure and technology transfer of this plant. Under these MoUs, the Gujarat government will provide land, incentives, and support to strengthen India’s private space ecosystem.

Azista details

Azista Space is an Indo-German joint venture, comprising Azista Industries Private Limited (India, Hyderabad-based) and Berlin Space Technologies GmbH (Germany). The company already has Asia’s first private satellite factory at Plot No. 16, Sarkhej-Sanand Road, Sanand GIDC, Ahmedabad, which is equipped with 30,000 sq ft of clean rooms, AIT (Assembly, Integration & Testing) lab and testing facilities. The existing factory has the capacity to manufacture 50 satellites annually, with a capacity expandable to 250, and 80%+ of the sub-systems, such as power system, communication, and control units, are manufactured in-house. This speeds up the build time by 250 times and reduces the cost by 40 times.

The aim of this new plant

The new plant is not just intended to manufacture spare parts or payloads, but to prepare for mass production. This will enable fast and cheap supply for mega-constellations (networks of thousands of satellites, such as Starlink). The main objective of this plant is to produce fully indigenous satellites and advanced optical payloads in India by the private sector.

It will be an end-to-end integrated facility, where everything from design to final production, testing and qualification will be done under a single roof. The plant will have state-of-the-art facilities, such as advanced clean rooms, calibration labs and R&D centres, thereby reducing dependence on imports and making Indian satellites competitive in the global market.

Azista’s main achievement

The company’s major achievement is the ABA First Runner (AFR) satellite. This satellite is the maiden (first) satellite of Azista BST Aerospace. It is the first such high-performance remote sensing satellite built by India’s private space sector, weighing 80 kg and designed for wide-swath medium-resolution optical imaging.

It is worth noting that the satellite weighs only 80 kg – that is, it is as light as a large suitcase. Its size is about 60 cm x 60 cm x 40 cm. It has a special camera, which takes pictures of the Earth. This camera takes pictures from about 550 kilometres above, in which even objects like cars are clearly visible. This is called ‘4.6 meter resolution’ – that is, objects smaller than 4.6 meters are seen separately.

The camera can take images of land up to 60 kilometres wide at a time, called a ‘wide-swath’. It can take colour photos (in red, green, and blue) and special types of photos, such as infrared, to determine plant health. The satellite orbits the Earth in a sun-synchronous orbit – that is, it passes over the same place at the same time every day, so the photos are always taken in the same kind of light.

This satellite can be used for tasks like monitoring the condition of crops in agriculture, whether water is needed or not, monitoring forests, rivers, pollution in the environment, new constructions, roads, floods, and where help is needed in times of earthquakes, etc.

This satellite was launched from America on 13th June 2023 on SpaceX’s Falcon-9 rocket. It was a shared ride, meaning many small satellites went together. It has now been operating in space for more than 2 years. It has taken thousands of photos, sent a lot of data and photographed more than 10% of the Earth. It is still working well and is planned to last for another 3 years.

Accelerating ‘Make in India’ and ‘Self-reliant India’

Gujarat Science and Technology Minister Arjun Modhwadia, while laying the foundation stone of this plant, said, “This facility of Azista Space will play a significant role in furthering the vision of a self-reliant India, as the entire design, development and testing of the satellite will be done under a single umbrella using indigenous technology.” He further added, “This project will strengthen India’s national security and strategic preparedness.” This means that the satellites built by the plant will create self-reliance in defence, agriculture, disaster management and other sectors.

The satellite manufacturing unit set up by Azista BST in Sanand is not just a project for the ‘Make in India’ and ‘Atmanirbhar Bharat’ campaigns, but an entire ecosystem shift. Till now, India often relied on foreign technology or components for its sophisticated satellites for security and border surveillance.

But now the situation will change. Apart from this, when a satellite is made in India, its design and the data sent through it remain completely under Indian control. This ‘self-reliance’ is extremely important from the point of view of security. Apart from this, India will be able to make and launch small satellites on a rapid basis as per its requirement, which was not possible earlier.

Global Manufacturing Hub: Many companies around the world are now looking for alternatives to China. This plant in Sanand presents India as a strong alternative to China in the space sector. Azista’s plant can manufacture 36 satellites annually. This means that India is now becoming a ‘wholesaler’ of space technology from a ‘retailer’. Seeing such successful private ventures, other foreign aerospace companies will also be motivated to invest in India and set up factories here.

Development of the MSME sector: Making a satellite is not the job of a single company; it requires thousands of small spare parts. The coming up of the plant in Sanand will give orders to hundreds of small and medium enterprises (MSMEs) around it to make sensors, bolts, panels and wiring harnesses. Gujarat is already at the forefront of engineering and manufacturing. Now the industries here will acquire the skills to make ‘space-grade’ parts, which will be the biggest achievement of ‘Make in India’.

India’s share in the space economy: According to a report, India’s share in the global space economy is currently only 2%, or $8.4 billion. The Indian government wants to increase this share to more than 8%, or $44 billion, by 2033. This plant will make a significant contribution to this.

Apart from this, ISRO will now be able to focus on big missions like Gaganyaan and Aditya L1, while private units like Sanand will take care of the work of building commercial satellites. This division will further boost ‘Atmanirbhar Bharat’.

Stopping Brain Drain: ‘Atmanirbhar Bharat‘ also means ‘Atmanirbhar Youth’. Till now, India’s best aerospace engineers used to go to America for NASA or SpaceX in search of opportunities. Now with such world-class factories on Indian soil and that too in a state like Gujarat, talented youth will stay in India and develop technology for the country.

Imports will decrease, and employment will increase: More than 80% of the sub-systems, like power system, communication, and control units in this plant, will be made in India. This will reduce imports, reduce costs and speed up the build time. The plant is ready for mass production, so that India can come forward in projects like mega-constellations of thousands of satellites. This project will make Gujarat a national leader in space technology and high-tech manufacturing and will create large-scale employment for the youth in fields like electronics, mechanical engineering, and remote sensing.

Gujarat: From research to global hub of space manufacturing

The most important thing is that Gujarat’s connection with space began with India’s independence. In 1947, Dr Vikram Sarabhai established PRL in Ahmedabad. It is called the ‘cradle of Indian space science’. It was from here that the initial scientific foundations of India’s space program were laid. Then, as a result of the tireless efforts of Indian scientists, ISRO was established in 1969, in which Dr Sarabhai’s contribution was major.

Apart from this, the Space Application Centre-SAC located in Ahmedabad is considered the heart of ISRO. SAC specialises in making remote sensing, communication and navigation payloads (the main equipment of satellites). 11 important instruments used in the Chandrayaan-3 mission, such as lander camera, altimeter and radar, etc., were prepared by the SAC centre in Ahmedabad. 80% of the landing site selection was also processed here.

Moving beyond research, Gujarat is now making waves globally in ‘satellite manufacturing’. Azista BTS Aerospace is Asia’s first private factory capable of ‘satellite mass production’. This plant has the capacity to manufacture 2 satellites per week, or about 100 microsatellites per year.

The government’s plan is not to limit Sanand to just one factory, but to make it a hub where everything from satellite design to testing can be done in one place. Apart from Azista, the process of setting up other supporting industries in Sanand is also underway. This cluster of Sanand is going to become a ‘satellite manufacturing capital’ not only for Gujarat, but for the entire South Asia. Looking at the government’s policies and the enthusiasm of the private sector, it seems that the next decade will be of ‘Made in Gujarat’ satellites.

(This article is a translation of the original article published on OpIndia Gujarati.)